Camfil Farr’s Self-Contained Isolation Systems are ideal for the control of airborne pathogens, viral contaminants and infectious organisms. These systems can be custom-designed to remove airborne particulate, gaseous contaminant, or a combination thereof.

Typical applications include hospital isolation rooms/wards and intensive care units. In applications where persons may come into the proximity of individuals with mycobacterium tuberculosis (TB), the U.S. Centres for Disease Control (CDC) has specified certain air quality control parameters.

For new projects or renovations, a minimum of 12 air changes per hour of clean air are required. For existing systems, the minimum air change requirement is 6 air changes per hour. In both cases the CDC Guideline is specific to the protection of employees and visitors to the facility. Camfil Farr’s Self-Contained Isolation Systems can assist your facility in meeting or exceeding these guidelines. (For a copy of these guidelines contact your local Camfil Farr Representative or Camfil Farr.)

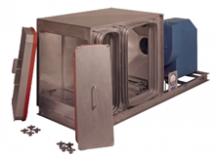

Available in various customizable configurations, each unit is reviewed by our engineering team and tested as a complete system to ensure suitability to task. Mechanical components are matched to filtration stages to assure deliverance of the rated air flow.

Camfil Farr has the ability to supply the system and the filters. Component compatibility and overall system quality are assured from a single-source manufacturer.